Project Description

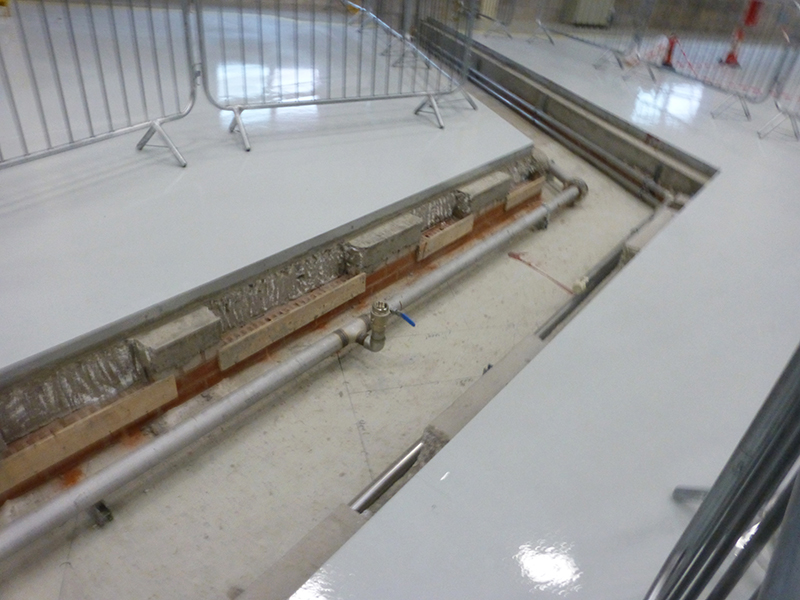

Essential service pipework required for the production process

Fibrelite Supply Bespoke Trench Covers over Concrete Trenches that house Essential Pipework and Service Supplies

Fibrelite Supply Trench Covers for Leading UK Aerospace Facility

Fibrelite’s range of standard and bespoke covers were designed and manufactured for this complicated application. The main requirement was easy access for operators who regularly need to enter these trenches that supply the manufacturing plant with essential services.

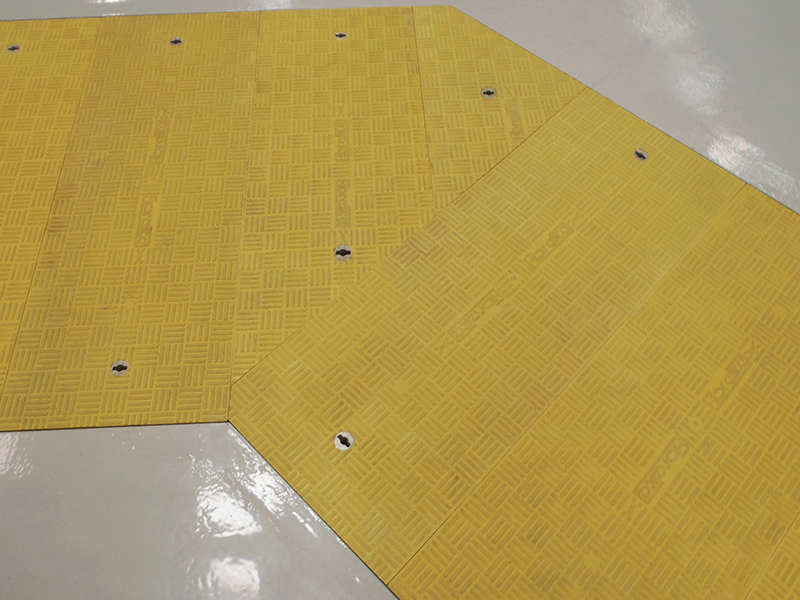

The production areas need to have fully flexible workstations with the constant movement of parts and equipment. As new wing assemblies are required the support stations move and therefore the services also move. The panels are lifted regularly to ensure production areas are working efficiently. For operators working within the facility, ease of access and safety are critical.

Essential service pipework required for the production process

Fibrelite covers needed to be manufactured to work with pre-installed steel supports

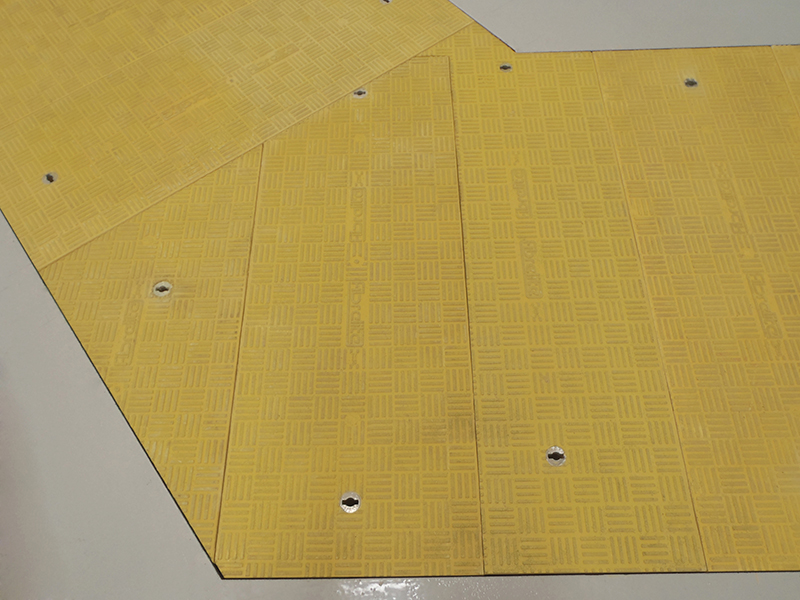

Complex corner trench design

Bespoke trench covers for complex corner sections

Sophisticated Highly Specialised Material

Fibrelite is the world leading manufacturer of glass reinforced plastic (GRP) composite manhole covers and trench covers. This sophisticated and highly specialised material is fast becoming recognised as the more effective modern alternative to traditional materials such as heavy steel and concrete.

The Fibrelite yellow C250 (25 tonne) load rated standard duty trench access covers

Chemically inert and corrosion resistant

Benefits of Fitting a Fibrelite

Upon request, Fibrelite can provide bespoke and custom solutions. This means that the panel dimensions, internal stiffeners and fibre architecture can be altered to optimise the performance of each panel based on project specific design criteria.

Advantages of fiber composite covers:

- Customised solutions

- Lightweight for easy and safe manual removal

- Load ratings from A15 to F900 (BS EN 124)

- Chemically inert and corrosion resistant

- Anti-slip/skid properties

- Improved health and safety practices

No Compromise on Performance

Upon request, Fibrelite can provide bespoke and custom solutions. This means that the panel dimensions, internal stiffeners and fibre architecture can be altered to optimise the performance of each panel based on project specific design criteria.