Project Description

Large Span: Fibrelite trench covers go up to 1600mm in length at D400 (40 tonne) load rating

Fibrelite Continue their Work Supplying Trench Access Covers to a UK Power Station

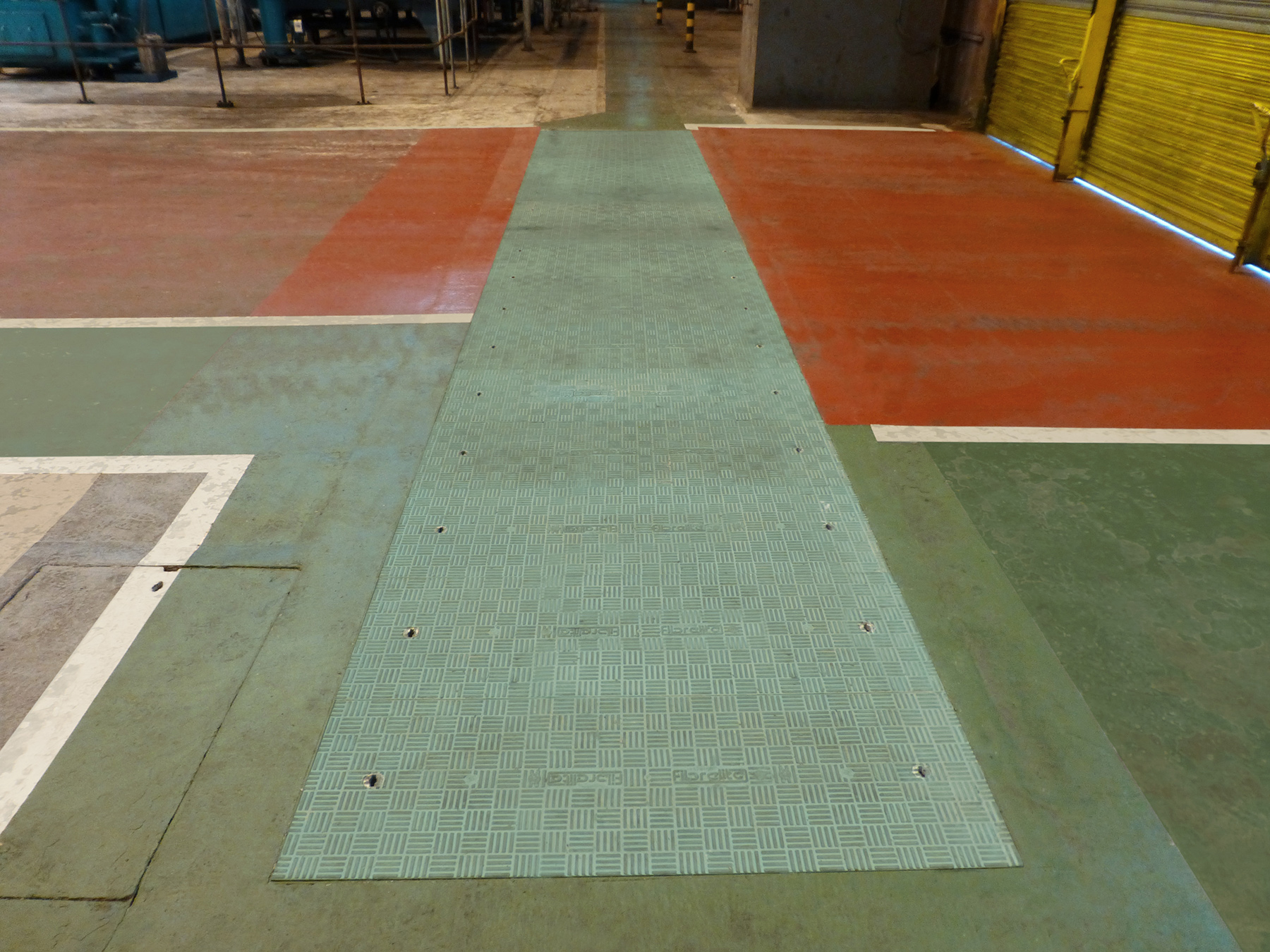

The second phase installation has been completed as Fibrelite supply 7.65m of 1350mm long trench access covers in D400 load

rating. Covers have now been installed in the entrance of the boiler room where HGV’s are frequently entering and exiting through the roller doors. The critical requirement was that the covers could withstand the imposed loading from the HGV’s.

This particular client required the covers to match the already coloured floor and Fibrelite was able to match exactly to the pale green colour.

Large Span: Fibrelite trench covers go up to 1600mm in length at D400 (40 tonne) load rating

Fibrelite can match to any RAL colour

Coloured Trench Covers

An important requirement for the customer was that the trench covers matched the surrounding area. All Fibrelite trench and access covers have the option to be supplied in a wide variety of colours, the pigment is introduced directly into the resin during the moulding process, ensuring that the colouring is not merely applied to the surface but evenly and completely infused throughout the cover. No maintenance is therefore required after install. Further customisation can be provided in the form of a logo, making the Fibrelite access cover truly versatile.

This UK Power Station removed crumbling and damaged concrete covers that were severely damaged and replaced them with Fibrelite’s lightweight trench access covers. Previously, a forklift and lifting equipment had to be used every time one of the old covers needed to be removed, a costly and time consuming exercise. Now two people can easily and safely remove the Fibrelite covers.

As shown in the images below the tired, cracked and crumbling concrete covers had not only seen better days, but caused on site

health and safety issues. All these hazards are eliminated with Fibrelite non-corrosive, non-cracking, slip resistant and incredibly strong composite covers.

Once removed the concrete covers would never sit back in the frame correctly

The previously installed old corroding and crumbling concrete covers

Benefits Overview:

- Lightweight reducing lifting and handling issues: The covers are easily removed by a two man lift, even at heavy duty load ratings

- Improved efficiency and productivity: Quick removal and no expensive lifting apparatus required, just the ergonomically designed Fibrelite lifting handle

- Corrosion resistant

- No resale value to the scrap market so will not be stolen

- Non-metallic and will not spark

- Composite is lightweight, strong and unlike concrete will not crumble or crack

- Guaranteed structural performance: All covers are tested to BS EN 124 standards