Project Description

The previously installed dangerous and corroded metal covers

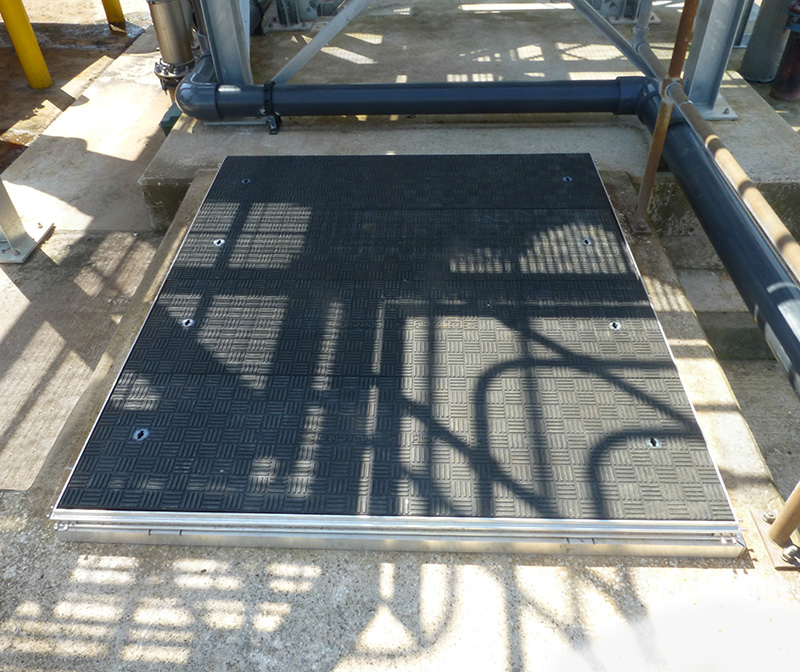

Fibrelite Supply Trench Cover arrangements over Waste Water Chambers

Fibrelite’s Corrosion Resistant Covers

Due to the nature of the harmful methane gases, the previously installed steel covers were badly corroded and dangerous. By modifying the resin matrix Fibrelite was able to offer a chemical resistant cover. Fibrelite’s composite covers are resistant to chemical and harmful gasses and are corrosion free. For these applications is the ideal replacement to conventional metal and concrete covers that can easily corrode and crack.

The modular cover design provided by Fibrelite offered single cover removal access where required. To have a similar option in traditional material like metal or concrete would require large heavy covers that would require specialist lifting equipment or spring / gas assist covers. The Fibrelite covers are only a one or two man operation with the use of special lifting handles.

The previously installed dangerous and corroded metal covers

The old heavy mechanical steel covers were replaced with the Fibrelite lightweight alternative

Easy Access for Operators

Fibrelite’s range of super light duty covers were designed and manufactured for this complicated application. The main requirement was easy access for operators who regularly need to enter these chambers that contain waste water in large underground tanks. The chambers were of various sizes and tended to be concrete in construction. The ease of fitting the Fibrelite system meant the frames could be bolted directly on top of the chamber. This meant the costly job of breaking out and re- concreting in was not required.

Sophisticated Highly Specialised Material

Fibrelite is the world leading manufacturer of glass reinforced plastic (GRP)glass reinforced plastic (GRP) composite manhole covers and trench covers. This sophisticated and highly specialised material is fast becoming recognised as the more effective modern alternative to traditional materials such as heavy steel and concrete.

Benefits over metal and concrete covers include:

- Lightweight for easy and safe manual removal

- Load ratings from A15 to F900 (BS EN 124)

- Chemically inert and corrosion resistant

- Anti-slip/skid properties

Benefits of Fitting a Fibrelite

- Customised solutions

- A fit and forget product that will not corrode or fade

- Improved productivity for both operational and maintenance crews

- Improved health and safety practices

- Technical support

Fibrelite Supply Custom Design Trench Covers for Leading UK Water Company

In conjunction with the designers, contractors and end user, the trench cover arrangement was designed specifically in line with the brief for this location in a busy waste treatment plant at Alfreton, Derbyshire. Therefore the covers had to be safe for people walking across with the cover treads incorporating a specialised anti-slip material. For operators working at the site ease of access and safety are critical.

Fibrelite’s super light duty composite trench covers were identified as the solution. Designed as a ‘fit and forget’ product, the maintenance free covers provide easy and safe access to the essential equipment.

Fibrelite’s access covers are lightweight, durable and very strong. Every Fibrelite cover is manufactured using high technology resin transfer moulded (RTM) production methods to create a highly engineered, monolithic composite product.

Specialised vent pipe could also be incorporated into the Fibrelite design

The Fibrelite A15 (1.5 tonne) load rated super light duty trench access covers

Highly Effective in Preventing Injuries Lifting

Fibrelite’s trench covers have proved highly effective in reducing health and safety issues and potential damage to essential pipework.

No Compromise on Performance

Upon request, Fibrelite can provide bespoke and custom solutions. This means that the panel dimensions and fibre architecture can be altered to optimise the performance of each panel based on project specific design criteria.