Project Description

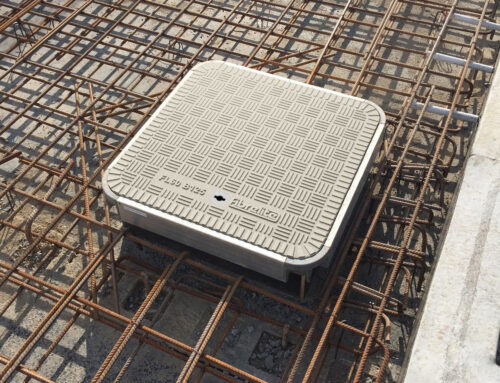

Fibrelite covers have an anti-slip surface

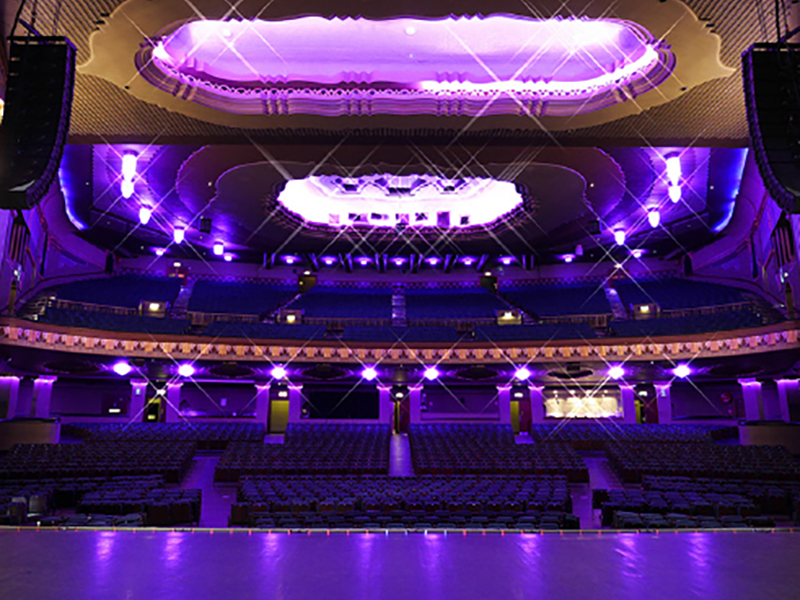

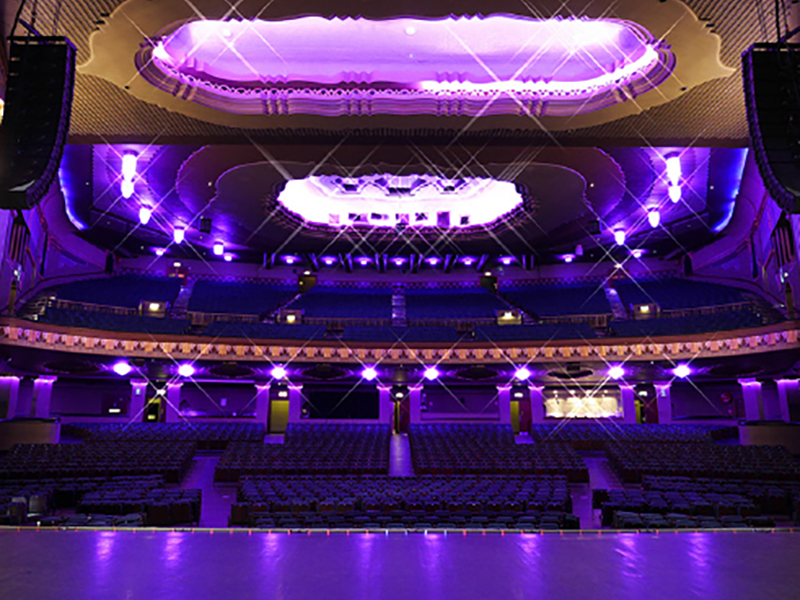

Fibrelite Supply Covering Solution to a Recently Refurbished London Theatre

The architects (Foster Wilson Architects LLP) who were project managing the refurbishment of the theatre tasked with providing a discreet and practical method of housing multicore cables that ran from the stage to the control desk during music concerts. Previously the cables had been run above ground subsequently causing damage to the beautiful interior of the theatre.

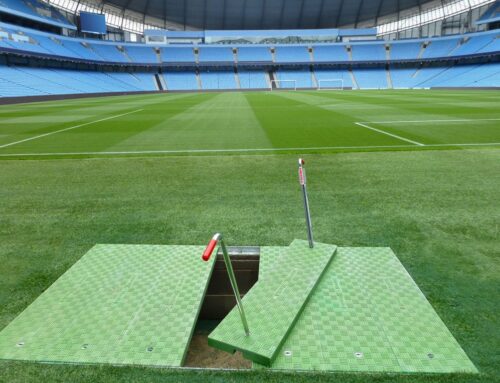

To accommodate the multicore cabling, two underground cable routes were cut into the floor. The cable routes needed to be covered with a lightweight maintenance free, cover that was readily removable by simple manual handling techniques but also sufficiently strong enough to withstand imposed loads from MEWP’s (mobile elevating working platforms) as additional refurbishment work on the building was required. In addition to these requirements anti-slip/skid was also a factor that need to be addressed.

Fibrelite supplied a bespoke encapsulating frame for both multicore cable routes along with a 1.5 tonne load rated trench cover to cover the cable trenches. The design was extremely challenging as not only did the cable trenches change in direction but they also changed in elevation. The Fibrelite cover incorporates an anti-slip material within the top treaded surface of the covers which provides unparalleled anti-slip/skid properties for a composite cover.

Fibrelite covers have an anti-slip surface

Lightweight Fibrelite covers

Fibrelite attended site regularly throughout the installation and liaised with both the architect and principle contractor to provide a solution to the highest possible standards within the projects build time frame.

The lead Architect, project managing the refurbishment commented on the solution provided by Fibrelite:

“Overall I think Fibrelite is a great solution to a difficult design problem for us of achieving both a robust and high load capacity cover to the multicore cables running for stage to control desk whilst maintaining low weight and easy access“

Easy single person lifting system

Sophisticated Highly Specialised Material

Fibrelite is the world leading manufacturer of glass reinforced plastic (GRP) composite manhole covers and trench covers. This sophisticated and highly specialised material is fast becoming recognised as the more effective modern alternative to traditional materials such as heavy steel and concrete.

Benefits over the more traditional, technologically inferior metal covers:

- Lightweight for easy and safe manual removal

- Load ratings from A15 to F900 (BS EN 124)

- Chemically inert and corrosion resistant

- Anti-slip/skid properties

No Compromise on Performance

Upon request, Fibrelite can provide bespoke and custom solutions. This means that the panel dimensions, internal stiffeners and fibre architecture can be altered to optimise the performance of each panel based on project specific design criteria.

Benefits of Fitting a Fibrelite

- Customised solutions

- A fit and forget product that will not corrode or fade

- Improved productivity for both operational and maintenance crews

- Improved health and safety practices

- Technical support